Facility Planning

Food Tech provides clear, upfront planning studies for your facility projects, whether they be greenfield or expansion.

Food Tech provides clear, upfront planning studies for your facility projects, whether they be greenfield or expansion.

One of the most effective methods for increasing productivity and lowering costs is to reduce or eliminate activities that are unnecessary or wasteful. A facility planning partner like Food Tech can help you do just that. We start by discussing with you the following critical items, so that we can best provide a full range of valuable facility planning and management services to help ensure you have the best tools available to make your project a success.

- Size of your facility based on current and future operational needs.

- Expected “design year” and when you anticipate running out of space.

- Life expectancy on current facility if renovated.

- Site utilization and best master plan(s) to pursue.

- Desired building materials and systems.

- Amount of funding available and time frame for completion.

- Anticipated ROI.

Our facility planning solutions include:

Feasibility Studies

Upfront planning is crucial to strategic business decisions, including food facility planning and construction. A feasibility study from Food Tech includes an evaluation of your entire operation to help you define current and future goals and needs. This helps you explore possible courses of action while avoiding costly missteps during construction.

Our feasibility studies cover the following areas:

- How the addition of new products might impact existing operations

- Expanding vs. renovating

- How ingredient and recipe changes impact existing operations

- LEED certification

- Co-pack vs. in-house decisions

- Manufacturing methodology

- Moving lines both intra-plant and inter-plant

- Short-term vs. long-term objectives

- Utility sizing and consumptions

- Assistance with payback and ROI analysis

- Capacity analysis

- Consolidation studies and due diligence services

- Facility optimization studies

- Code search (building, USDA, FDA, etc.)

- Engineering, safety, and ergonomic studies

- Optimal layout (process flows)

- Sanitation studies

The final product of our in-depth study is the Design Report Booklet—a document that contemplates important features of a facility’s expected life cycle as well as the costs associated with building and operating the facility.

Facility Sizing/Process Programming

Facility sizing is a crucial step in the food facility design and planning process, in both new construction and renovations. We utilize a methodical engineering approach supported by an analysis of throughput and inventory requirements to help determine the size of facility that is best fit to your needs.

Facility sizing is a crucial step in the food facility design and planning process, in both new construction and renovations. We utilize a methodical engineering approach supported by an analysis of throughput and inventory requirements to help determine the size of facility that is best fit to your needs.

We also leverage innovative architectural programming and preconstruction services throughout the process.

Areas addressed include:

- Warehouse size and physical attributes

- Site flow and parking requirements

- Storage equipment definition

- Dock door requirements

- Support equipment definition (e.g., battery chargers)

- Work process definition

- Productivity and staffing calculations

Our approach will help you realize the benefits of facility sizing and process programming when it comes to food facility engineering and food master site planning.

Site/Facility Selection

The right location is a top priority for new site and facility selection, but it can be a tough choice to make when all of the factors are considered. Our years of experience and in-depth understanding of food facility planning can help you choose the ideal site for your facility. We include factors such as labor availability, tax liabilities, logistical concerns, and competitor identification in our holistic site selection approach.

Our site selection services consider an exhaustive list of factors to help position your facility in an ideal location for helping maximize economic incentives while minimizing operating costs and liabilities.

- Labor market analytics

- Labor supply/demand forecasting

- Competition saturation analysis

- Customer analytics

- Infrastructure assessment

- Utility assessment

- Unionization analysis

- Transportation analysis

- Business climate assessment

- Geo-political risk assessment

- Natural disaster risk evaluation

- Geographic information systems analytics and mapping

- Employer interviews

- Community due diligence

- Food feasibility studies

Master Planning & Preliminary Design

Food Tech employs a full team of professional architects, engineers, and project managers to help you define the requirements of your food facility construction project through master site planning and preliminary design.

Food Tech employs a full team of professional architects, engineers, and project managers to help you define the requirements of your food facility construction project through master site planning and preliminary design.

Our master site planning team helps identify the design parameters and constraints that can help keep construction on-time and on-budget.

Preliminary design services include:

- Master site planning/Facility planning

- Programming

- Space planning

- Feasibility studies

- Conceptual design

- Site analysis

- Existing facility evaluation

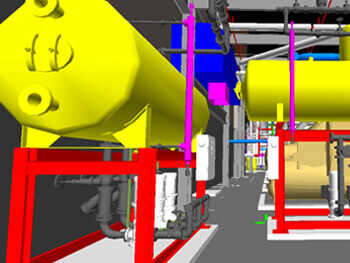

- 3D studies

Our experts will evaluate the space needs and requirements for the new facility and then develop schematic plans. From there, cost estimates can be prepared and the project can officially move into the design-build phase.

Estimating/Scheduling

For many food companies, getting a new product to market fast is key to their growth and profit, which is why all of Food Tech’s services—including construction estimating, construction scheduling, and construction services—are designed to speed up the overall timeline and eliminate redundancies. Our professional estimating and scheduling solutions optimize project timelines, helping you save time and increase profitability.

Estimating/Scheduling services are offered as a part of the following:

- Facility planning

- Process programing

- Strategic logistics network analysis

- Architecture and engineering

- Design-build and construction